What is repetitive manufacturing in SAP?

SAP supports a variety of industrial processes, including SAP Repetitive Manufacturing (REM). There is a manufacturing technique that is more suited to one sector than the other. When deciding on a manufacturing process, factors including production rates, consumer needs, and product complexity come into play.

Repetitive manufacturing is a production method that is based on time rather than on order or lot. The same product will be produced for a certain length of time, and it is unlikely that it will change frequently. Interim items are not stored since the product is processed at a steady rate. Back-flushing is used to confirm orders, and the settlement is handled by the product cost collector. The shop floor activity can be carried out with only planned orders.

The commonly used manufacturing processes are:

- Discrete manufacturing

- Repetitive manufacturing

- Process manufacturing

In sectors where manufacturing is quantity-based rather than order-based, the SAP Repetitive Manufacturing (REM) approach is employed. Another important feature of repeated manufacturing is that it is time-based, with production taking months or years. SAP repetitive manufacturing is used in the following industries:

Electronics\sAutomobiles

Let’s use a gadget like a phone as an example. Once the design has been completed, it will be manufactured in large quantities. The production is not based on orders; instead, the goal is to create a certain quantity in a certain amount of time. The time period or planning horizon, in this case, may be prior to the launching of the new model. As a result, manufacturing will be determined on quantity and time. Repetitive Manufacturing (REM)

Another important characteristic of SAP repetitive production is that goods follow a predictable pattern of activity. This indicates that the routing is straightforward and that there are few route options. The fundamental differences and similarities between discrete and repetitive production are listed below.

SAP Repetitive Manufacturing Process

Both Make-To-Order (MTO) and Make-To-Stock (MTS) repetitive manufacturing processes are supported by SAP:

MTS: There is no reference to an order in the production process. Independent needs that have been planned are utilised to create demand in the system. When sale orders are received, the warehouse stock will fulfil them.

MTO: This is referred to as sales order-based manufacturing. A reference to the sale order will be included in each production order. With the sale order assignment, stocks are kept up to date.

SAP Repetitive Manufacturing Profile

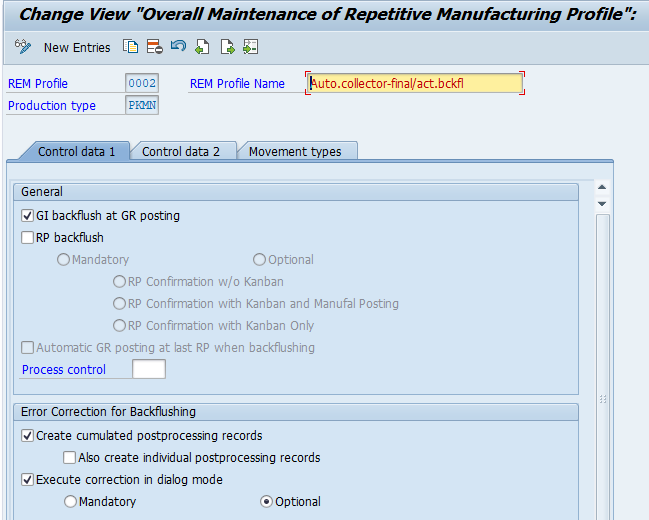

The key to a successful REM setup in SAP is the Repetitive Manufacturing (REM) profile. The REM profile determines how REM is performed in the system. This may be done by utilising the transaction code OSPT or by following the SAP configuration method below. Transaction code OSP2 can be used to modify existing REM profiles.

IMG -> Logistics -> Production -> Repetitive Manufacturing -> Control -> Create repetitive manufacturing profile using assistant.

The REM profile contains the below information:

- Types of REM production: The first step in creating a profile is to choose a production type. We must decide whether to adopt the MTO or MTS manufacturing approach.

- During inventory management, reporting points are used to record consumption data such as work in progress and stock management. This is similar to a discrete manufacturing milestone activity.

- Automatic goods movement: Determines if a backflush or goods movement is required during reporting point confirmation.

- Backflush activities posting: Determines whether backflush activities must be recorded to a product cost controller.

- Plan orders are being firmed up: This option ensures that the MRP run does not alter the plan order.

- Automatic stock determination: The system will offer available stocks for consumption if the automatic stock determination mechanism is defined.

- Batch determination method: If the material is batch-managed, a batch determination technique can be defined and assigned to the REM profile. The system will then make batch recommendations based on the stated criteria.

- Posting movement types: We may describe the movement types that will be utilised for various postings. The default movement kinds will be suggested by the system. 261 is the movement type for products issue, for example. We can keep track of all the customizable movement kinds in the REM profile if there are a lot of them.

SAP REM full cycle scenario with basic step

- Company manufactures product in large numbers and production is quantity-based and period based not order-based.

- Repetitive manufacturing is mainly used for production scenarios with high product stability, high repetition rates, and low product complexity.

- In master data production versions and product cost collector is must where this is not mandatory in discrete manufacturing.

- Product will not change frequently.

- Confirmation is from Backflushing.

- Planned orders are sufficient to carry out shop floor activity.

- In REM there is no process to convert planned order to production order.

SAP REM Full Cycle scenario

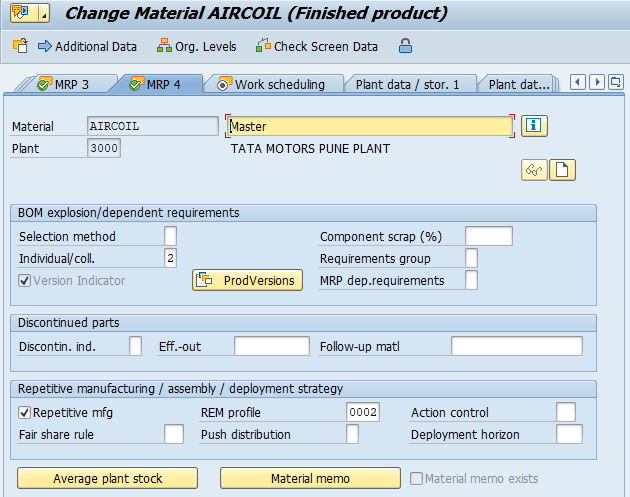

- Material Master- MM01/MM02

- BOM- CS01/CS02

- WC- CR01/CR02

- Rate Routing- CA21/CA22

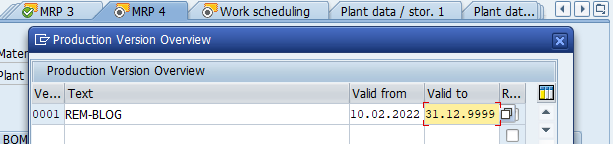

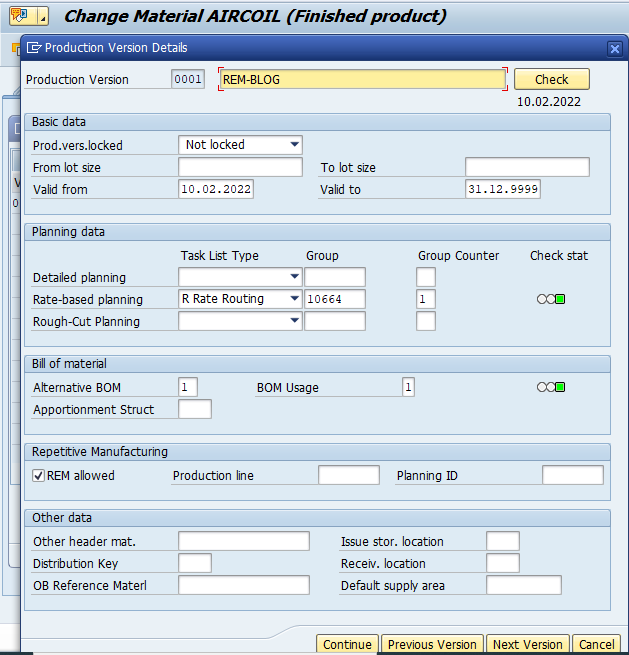

- Production Version- C223

- REM Profile- OSP2

- PIR Creation- MD61/62

- MRP RUN- MD02

- Product Cost Collector- KKF6N

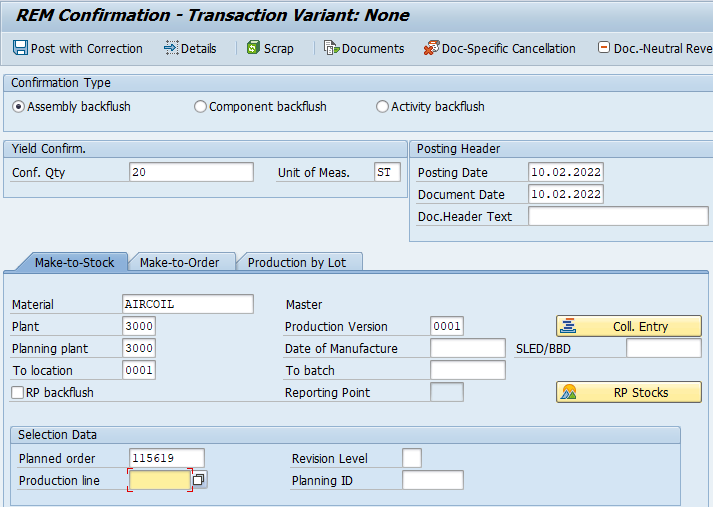

- REM Confirmation- MFBF

Create the REM Profile: By using T-code OSP2

- Create the finished material with Repetitive mfg. indicator and REM profile maintained in material master see view MRP 4 views, (MM02)

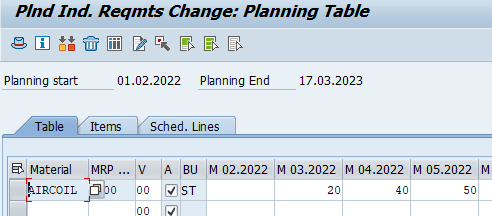

- Create the Plnd.Ind. Reqmnt (PIR) for the finished material Air coil with help of the T-code: MD61

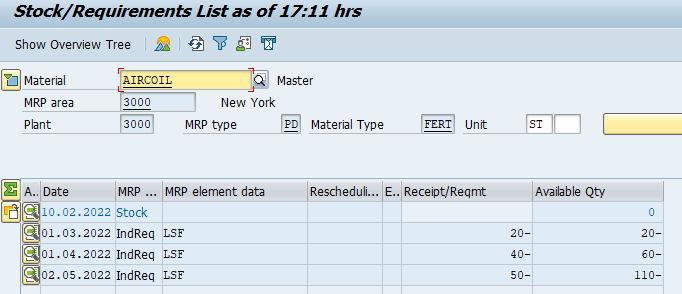

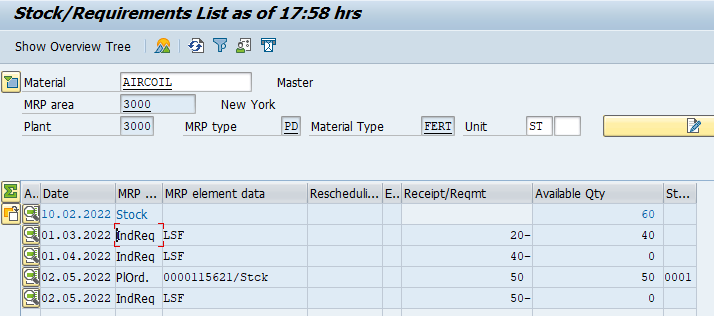

- In below pic of the stock requirement list after generating the demand without MRP RUN. (T-codes: MD04)

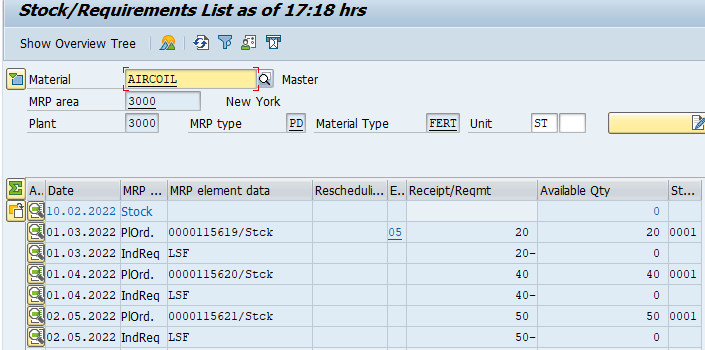

- After MRP RUN with the help of MD02 for finished material.

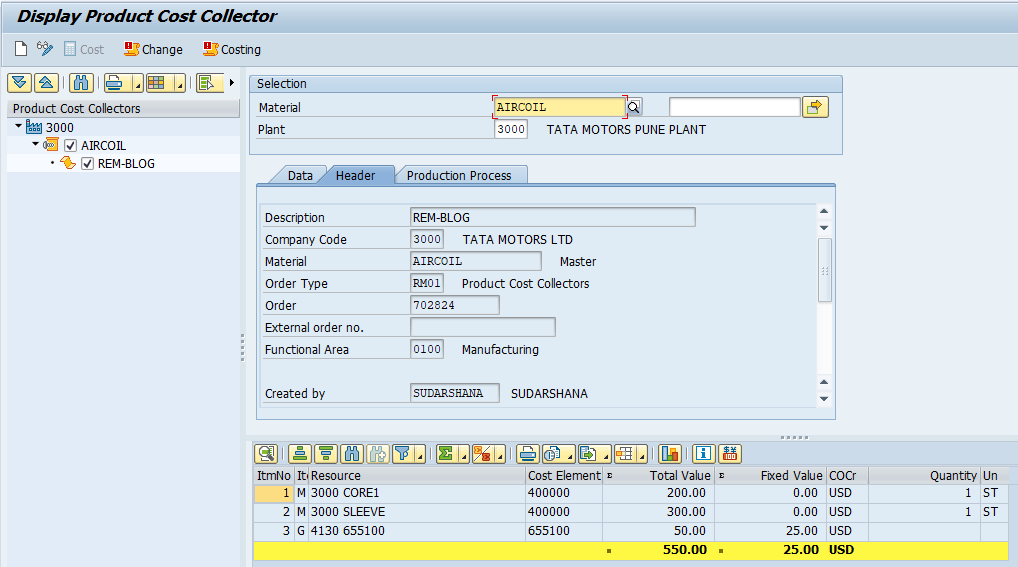

- Preliminary costing for the product cost collector.

Using T-code: KKF6N for create Preliminary cost estimation in REM.

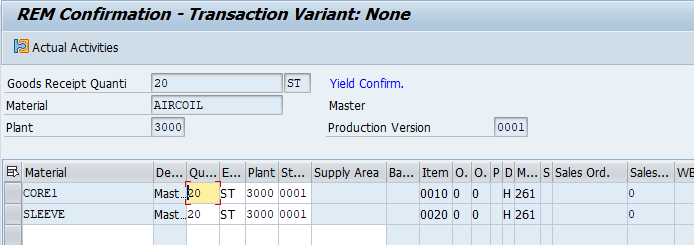

- REM Confirmation through planned order or finished material using MFBF, here we selected the planned order.

Post with correction in tool bar of REM confirmation.

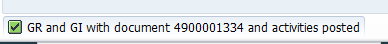

- After saving system posted GR and GI document (As per REM profile setting GR and GI done at same time)

- After the confirmation of the both planned order, good receipt done automatically.

Enroll at eLearning Solutions to become a SAP PP Expert, which is a stepping stone to a professional career, and learn SAP PP or any other basic coding language. SAP Training in Pune at eLearning Solutions is a great career choice since Orange eLearning Solutions is a great place to learn new technologies.

Training at eLearning Solutions and certification program ensures that you have a thorough understanding of the SAP PP Training’s essential themes. Getting certified in SAP PP not only increases your earning potential but also validates your understanding of the abilities required to be an effective PP Consultant. The certification attests to your capacity to deliver consistent, high-quality results with greater efficiency.

Interested in SAP PP Courses? Fill Your Details Here

Error: Contact form not found.

WhatsApp us

WhatsApp us