For those navigating the intricacies of SAP inventory management, understanding goods movement types is crucial. These three-digit codes act as the hidden language of stock movements, dictating how materials flow in and out of your SAP system. This blog delves deep into the world of SAP goods movement types, empowering you to optimize your inventory practices and achieve greater transparency.

What are Goods Movement Types?

Goods movement types represent the various transactions that affect your inventory levels in SAP. Each type signifies a specific action, such as goods receipt, delivery, transfer, or consumption. By understanding these codes and their purposes, you gain valuable insights into the movement of materials within your organization.

Key Goods Movement Types

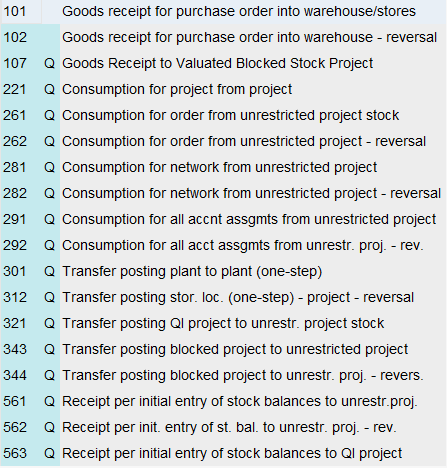

The vast world of SAP goods movement types can be overwhelming, but here are some of the most common and essential ones:

- 101 – Goods Receipt: Used when materials are received from a vendor or another plant.

- 102 – Return to Vendor: Refers to returning goods to a vendor.

- 201 – Goods Issue: Represents issuing materials for production, consumption, or other purposes.

- 202 – Delivery: Signifies delivering finished goods to a customer.

- 301 – Transfer to Stock in Transit: Used to move materials between storage locations within your organization.

- 303 – Goods Receipt at Storage Location: Records the arrival of transferred materials at the destination location.

- 311 – Transfer Posting: Used for transferring ownership of materials without physical movement.

- 501 – Warehouse Movement Within One Plant: Signifies moving materials within the same plant without changing ownership.

Special Goods Movement Types

Apart from the core types, SAP offers specialized codes for unique scenarios:

- 531 – Return from Customer: Handles returns received from customers.

- 541 – Inventory Difference Posting: Used to adjust inventory levels due to discrepancies or physical counting.

- 551 – Movement Type for Scrapped Material: Records scrapping or disposal of materials.

Optimizing Your Operations: Leveraging Movement Types

Understanding movement types empowers you to:

- Track inventory movements accurately: Gain real-time insights into material flow and identify potential issues.

- Control material usage effectively: Monitor consumption and optimize resource allocation.

- Simplify stocktaking and audits: Ensure accurate inventory records and facilitate smooth reconciliations.

- Improve logistics and supply chain efficiency: Enhance traceability and optimize material movements.

Beyond the Code: Additional Considerations

Remember, movement types are just one piece of the SAP inventory management puzzle. Consider these factors for a holistic approach:

- Customization: You can customize certain movement types to specific needs.

- Authorization controls: Define user permissions for specific movement types to ensure data integrity.

- Integration with other modules: Leverage seamless integration with other SAP modules like production and sales.

Conclusion:

Mastering SAP goods movement types unlocks a wealth of information and control over your inventory management. By understanding their meanings, applications, and potential customizations, you can optimize your SAP system, streamline operations, and achieve greater inventory transparency. Embrace this knowledge and watch your SAP inventory management flourish!

You may be interested in:

How Many Total T-Codes (Transaction Codes) Are There in SAP?

Which software testing is in demand ?

WhatsApp us

WhatsApp us