The procurement process begins with making a buy request and finishes with receipt confirmation. In the entire cycle, one of the significant parts is split valuation in SAP MM. While making buy orders, material cost is a compulsory field and it not entirely set in stone. It happens in light of the fact that material valuation is kept up with in the SAP framework in the material expert. Material valuation addresses mix between MM and FI (Financial Accounting) modules, since it refreshes the overall record accounts in monetary bookkeeping.

Optimize Procurement: Split Valuation in SAP MM for Efficient Cost Control

In several organizations, the challenge arises when one item needs to be both purchased and produced in the same plant. While bought materials are typically valuated by the price tag, delivered materials are usually costed based on their internal costing rates. In fact, bought materials are thus normally maintained using the split valuation in SAP MM, with the moving average cost (v-cost), while delivered materials are valuated with a standard cost (s-cost).

It is generally not suggested (particularly from a calculated and ace data of interest of view) to set up two unmistakable materials in a similar plant for oneself and a similar item only because of an alternate cost control approach. This approach bears redundancies in the expert information upkeep and a disproportional exertion in the support of cost records for the deals cycle and so on.

A more proficient arrangement without keeping two materials is the utilization of the split valuation approach. This SAP-standard arrangement permits valuating bought materials as indicated by the v-cost of course, while delivered materials can be valuated with the s-cost naturally.

Split valuation

It helps in valuating the supplies of a material in a similar valuation region (organization or plant) in an unexpected way. A portion of the models where parted valuation is required are as per the following

Stock that is obtained remotely from a merchant has an alternate valuation cost than the supply of an in-house creation.

Stock got from one merchant is valuated at an unexpected cost in comparison to the stock got from another seller.

Same material having different clump might have different valuation costs.

Split Valuation should be actuated prior to setting some other setup. Follow the means given beneath to initiate split valuation.

Way to Actuate Split Valuation

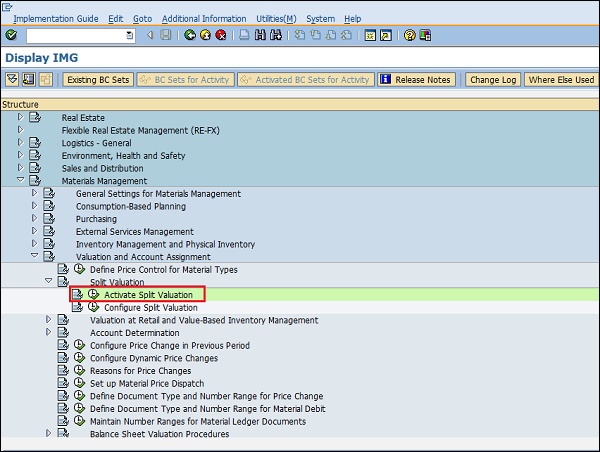

IMG ⇒ Materials The executives ⇒ Valuation and Record Task ⇒ Split Valuation ⇒ Actuate Split Valuation

TCode: OMW0

#Stege 1 − On the Display IMG screen, select Activate Split Valuation by following the above path.

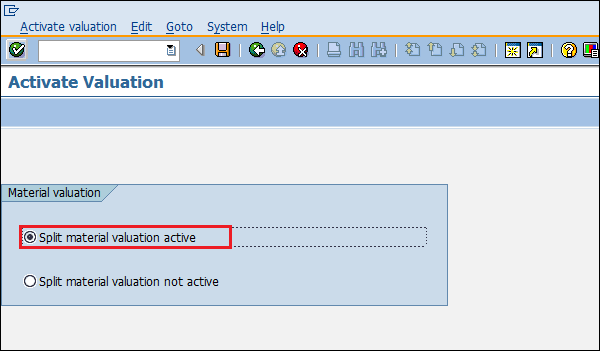

#Stege 2 − Click the option Split Material Valuation Active. Click on Save. Split valuation is now activated.

Split Valuation Configuration

Follow the means given beneath to do part valuation design, for example, characterizing valuation class and valuation type.

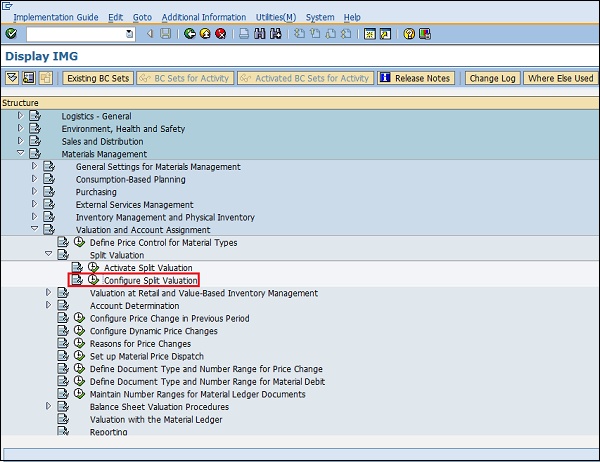

Way to Arrange Split Valuation IMG ⇒ Materials The board ⇒ Valuation and Record Task ⇒ Split Valuation ⇒ Arrange Split Valuation

TCode: OMWC

#Stage 1 − On the Presentation IMG screen, select Arrange Split Valuation by following the above way.

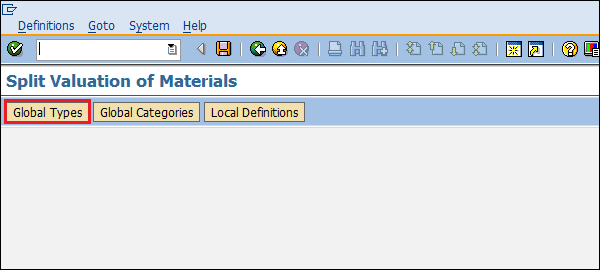

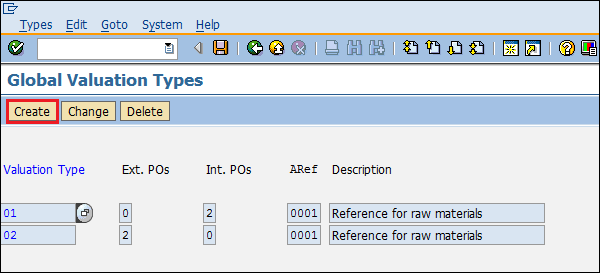

#Stage 2 − Click Global Types to create valuation type.

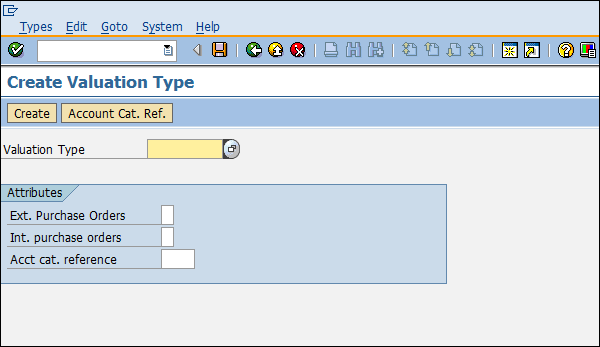

#Stage 3 − Click the Create button.

#Stage 4 − Give the name of the valuation type. Click on Save. Another Valuation Type will be made.

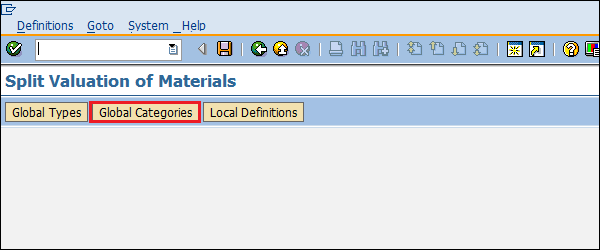

#Stage 5 − Presently go to similar screen and snap Worldwide Classes to make valuation classification.

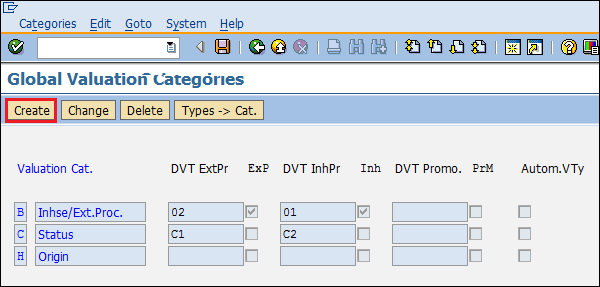

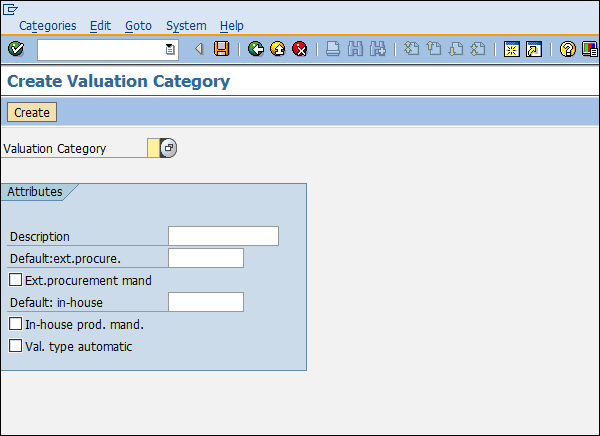

#Stage 6 − Click the Create button.

#Stage 7 − Give the name of the valuation class. Click on Save. Another Valuation Class will be made.

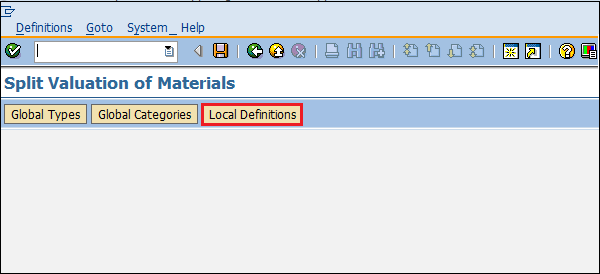

#Stage 8 − Presently go to similar screen and snap Nearby Definitions to plan valuation type and valuation classification.

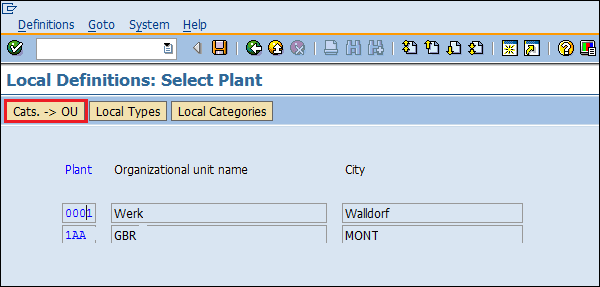

#Stage 9 − Click the Cats. → OU button..

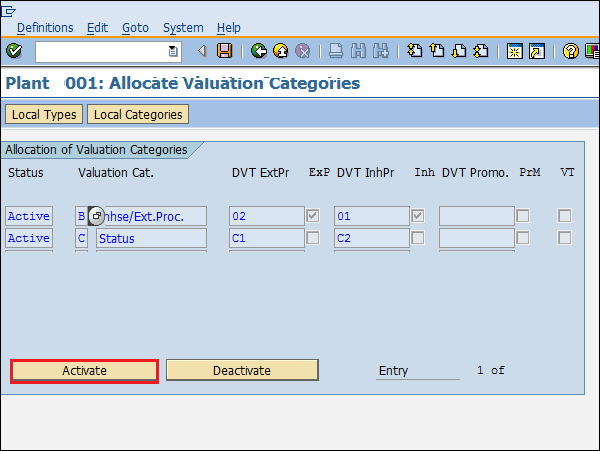

Stage 10 − Give valuation type, valuation class, and set the status as dynamic, and afterward click the Initiate button. Valuation class and valuation type are presently planned and both are initiated.

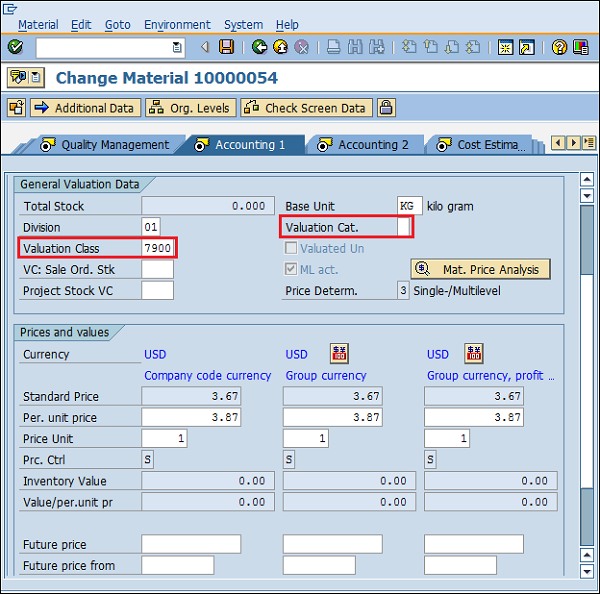

In the wake of keeping up with the valuation type and valuation class, you can specify them in the material expert as displayed beneath.

Go to mm02 (Change screen for material expert). Here you can keep up with the valuation class and valuation class in bookkeeping view. On this premise, valuation of the material will be finished in a buy request.

Conclusion:

In the realm of procurement and material management, split valuation in SAP offers an efficient solution for organizations to handle diverse material valuation needs within a single valuation area. It allows for distinct valuation methods for materials, simplifying processes, reducing data redundancies, and ensuring financial accuracy throughout the procurement cycle. By understanding and implementing split valuation, businesses can optimize their operations and maintain transparent financial records effectively.

FAQs

What is the purpose of split valuation?

On the off chance that a material is liable to part valuation, the material is overseen as a few fractional stock and every halfway stock is valuated independently. Each exchange that is pertinent for valuation, be it a merchandise receipt, products issue, receipt or actual stock, is executed at the level of the incomplete stock.

How do you identify split valuated materials in SAP?

A valuation type is a key that recognizes split-valuated supplies of a material and demonstrates the quality of an incomplete stock. The valuation class is allocated in the material expert record, and the valuation type is chosen during material exchanges, for example, merchandise issue and products receipts.

What is batch management in SAP MM?

Batch Management’ alludes to the whole of the coordinated operations process underway offices or plants, from obtainment to deals, across assembling in ventures like pharma, mining, FMCG, retail, aviation, and some more

What is valuated and non valuated material in SAP MM?

non valuated material is kept up with according to amount and not based on its worth, though non stock things are quickly consumed after the proucrement and not mainited in stock. Non-valuated is the point at which you keep stock just according to a quanity perspective.

What is class type 023 in SAP MM?

As an extraordinary component of the characterization framework, class type 023 has an item progressive system for object types Material and Group. In this article order, materials capability like classes. At the point when you relegate a material to a class of class type 023, you can limit the permitted upsides of the qualities.

WhatsApp us

WhatsApp us