SAP PP (Production Planning) Certification: Overview and Career Opportunities

What is the demand for the SAP PP module? In the current scenario, there is an enormous demand for SAP PP Certified professionals. As only 7 out of 10000 professionals are having expertise in SAP PP, there is a huge demand for entrants as well as experienced people in this field. SAP PP module certification can help candidates aspire for lucrative job opportunities as senior consultants, SAP Production Planning Consultants, assistant managers, and senior-level managers. SAP PP received attractive pay packages for recent entrants with nil experience; this SAP module is indeed worthy of a look. What is the demand for the SAP PP module?

So, gear up to experience the powers of SAP PP and take your career to the next levels of success – today.

The Introduction of SAP production planning and navigation concepts.

- Production Planning is the process of aligning demand with manufacturing capacity to create production and procurement schedules for finished products and component materials.

- SAP PP is an important module of SAP. It tracks and makes a record of the manufacturing process flows, for example, the planned and actual costs. Also, goods movements from the conversion of raw material to semi-finished goods.

- It is fully integrated with the other SAP modules: SD, MM, QM, FICO & PM.

SAP Education has designed SAP PP exam based on implementation and customizing areas which can cover the entire scenario of SAP Production Planning and Manufacturing. Following is an introduction to SAP production planning and navigation concepts.

- Set up and apply production-relevant master data.

- Sales and Operations Planning – which develops the skills to forecast production and sales plans by future, present and historical data.

- Material Requirements Planning and the various parameters for calculating the overall needs of the planning run.

- Shop Floor Control – apply production orders for discrete manufacturing; releasing the order sheets for production and their settling; and goods movements.

- Capacity – planning and evaluation.

- Lean Manufacturing (PP-REM PP-KAB) – which is a process based on the system of pulling KANBAN cards for generating the replenishment cycle.

- Product Cost Planning, which evaluates time values and the value of component materials for determining the product cost.

- The components related to Reporting and Analysis

The basic skills required for a career in SAP PP

- Degree from a recognized institute/ university and a good educational background.

- Basic knowledge of information and computer applications.

- Prior knowledge and hands-on experience of production planning and ERP tools

Scope and Opportunity of a Career in SAP PP

SAP Production Planning is one of the biggest modules in the current scenario. the top paying companies in the US are Capgemini, Accenture, Amgen Tampa, and others; The average salary for “sap pp” ranges from approximately $75,566 per year for Business Analysts to $109,874 per year for SAP Lead.

SAP PP Certification mostly Suited to

- Project team members

- Managerial staff in the department of production and purchasing trainers

- Business analysts

- IT staff

- Consultants

- Inventory Managers

After receiving a certification in this course, they can perform their tasks with the help of SAP Production Planning tools and software applications –accurately and efficiently. What is the demand for the SAP PP module?

How to Prepare for SAP PP Certification?

SAP Production Planning (PP) Certification consists of 80 multiple choice questions which you need to complete in 180 minutes. SAP has released exams C_TSCM42_67 and C_TS420_1709 based on the latest version of SAP ERP. The passing score of SAP PP Certification is 63% and 60% for the respective exam code. This exam will cost you USD 500 excluding training and material. SAP PP Certification validates your business consulting knowledge for SAP Production Planning and Manufacturing. You can gain the following credentials by passing of SAP PP Certification.

- C_TSCM42_67 – SAP Certified Application Associate – Production Planning & Manufacturing with SAP ERP 6.0 EHP7

- C_TS420_1709 – SAP Certified Application Associate – SAP S/4HANA Production Planning and Manufacturing (1709)

Organization Structure in SAP PP

In any live Production Planning module, locations of manufacturing plants and storage within the plants should be available in the system.

Importance of Plant and storage locations in Production Planning-

- All Production master data is created at the Plant level.

- Planning activities are also performed at the Plant level.

- Production Confirmation process and related goods movement occur at the plant and storage location level.

Master Data in SAP PP

Master data is generally static for any company and is very rarely changed depending on the requirement. There are 5 master data to be maintained in the Production Planning module.

- Material Master

The material master contains information on all the materials that a company procures, produces, stores, and sells. It is a number that uniquely identifies a material master record, and hence a material.

Materials with the same basic attributes are grouped and assigned to a material type such as finished, raw material, etc.

It is used for the following purposes:

- To purchase materials

- For Goods Movement postings such as goods issue or receipt in inventory management and also for physical inventory postings

- In invoice verification for posting invoices

- In sales and distribution for sales order fulfillment process

- In production planning and control for material requirements planning, scheduling, and production confirmation processes.

- Bill of Material (BOM)

A bill of material is a complete, formally structured list of the components together with the quantity required to produce the product or assembly.

BOM’s are used in material requirement planning and product costing.

You can also create up to 99 alternative BOMs for a single product.

For Products having variants, you can create Super BOM, which has all possible types of components used to manufacture different types of variants, and the appropriate component is selected based on characteristics chosen in the Sales Order.

For example, the Product Cycle can contain all types of frames (with different colors and sizes) and the desired frame is selected in production order based on color and size chosen in the sales order. the demand for the SAP PP module

-

Work Center

A Work Center is a machine or group of machines where production operations are performed. Work centers are used in task list operations (Routings).

It contains the data for

-

Scheduling

-

Capacity

-

Costing

-

Routing

Routing is nothing but a sequence of operations performed at the Work Center. It also specifies the machine time, labor time, etc. for the execution of operations.

It is also used for scheduling operations and used in standard cost calculation of the product.

-

Production version

The production version is a combination of BOM and Routing data for production. It is a linkage between BOM & Routing and determines the manufacturing process.

There can be multiple production versions as per different manufacturing processes to produce the product.

What is the demand for the SAP PP module?

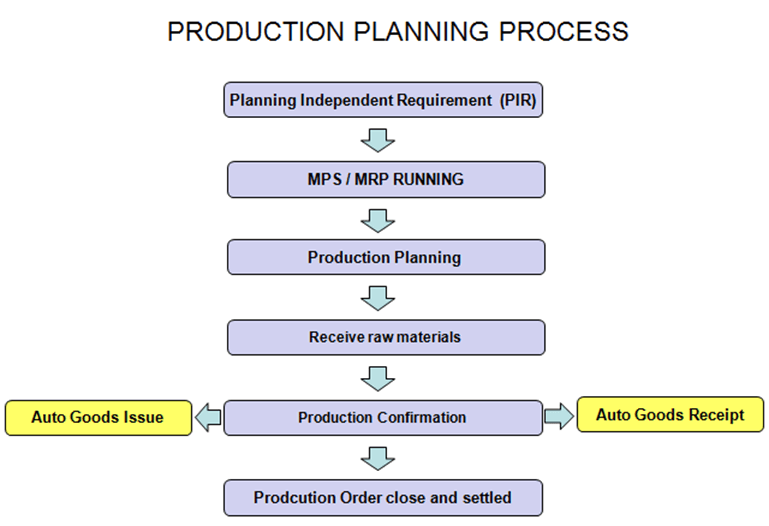

Production Planning Cycle

Production Planning and Control consist of 2 obvious processes of Planning and Execution.

Planning

Production planning is generally done from the budgeted sales plan. Planning is based on the Sales plan to meet the sales requirements as per the production cycle times. Demand for the Product is entered through demand management in the form of the planned independent requirement (PIR). This data from demand management becomes the input to Material requirement planning (MRP).MRP checks for the availability of various raw materials used for production at different stages using the master data such as Bill of material (BOM) and available current plant stocks.

In case of material shortage, Purchase requisitions are created for materials that are externally procured, and planned orders are created for in-house produced materials.

These purchase requisitions and planned orders initiate the Procurement Cycle and the Execution Cycle of Production respectively.

As MRP works with infinite capacities, capacity leveling must be done to avoid any capacity bottlenecks.

Execution

These Planned orders are converted to Production orders and are scheduled as per the production timings using master data such as routings.

Production Orders are released by the Production Supervisor on the shop floor, and material availability checks can also be carried out to check if there are any missing components.

Production is carried out based on the activities maintained in the Routing where the master data like Work Center is mentioned against each operation in the Routing.

Once the production is completed, the Confirmations of orders are executed, and goods movement for material consumptions & goods receipt are posted against the Order. Hence, the Order gets the Delivered (DLV) status, and the material is received into the desired storage location.

Usually, at the month-end before doing order settlement, the production order needs to be set to technically completed status to calculate production variances by the controlling personnel. the demand for the SAP PP module

What is the demand for the SAP PP module?

Demand Management

The function of Demand Management is to estimate requirement quantities and delivery dates for finished products and important assemblies. Demand Management uses PIR (planned independent requirements) and customer requirements.

Planning strategies must be defined for a product. It represents the methods of production for planning and manufacturing. There are two methods by which we can do this.

Make to Stock: Production of goods without having sales orders, i.e., the stock is produced independently of orders.

Make to Order: This strategy applies to the production of material for a specific individual sales order or line item.

Material Requirement Planning (MRP)

MRP determines any shortages and creates the appropriate procurement elements. It does net requirement calculation and generates planned orders for in-house produced materials and purchase requisition for raw materials.

It does lead time scheduling and calculates production dates in planned orders.

It explodes the BOM and generates procurement proposals at each BOM level.

Capacity Planning & Leveling

Capacity Planning is used to analyze the capacity overloads at the work center and shift the orders to avoid any capacity bottlenecks.

Capacity requirements are generated via MRP on Work Center and since MRP works with infinite capacity and plans everything on work center without considering any capacity constraints. It is required to level the capacity at the work center.

Capacity can be leveled at each work center through the planning table to create a constraint production plan. What is the demand for the SAP PP module?

Production Orders

The output of MRP will be “Planned Orders”, which needs to be converted to production orders for further execution of the process.

The Production Order is firmed receipt element, which is not affected by MRP run, unlike Planned Orders.

- Production Order is a document that specifies what material needs to be produced and in what quantity. It also contains the BOM components and routing operation data to be performed at the work center.

- Production Order is released for execution, and material availability checks can be carried out which determines if there are any missing components.

Production Order Confirmation

When goods are produced physically on the shop floor, then the production order must be confirmed.

During confirmation, components materials can be consumed automatically via backflush mechanism and Goods receipt of material can be performed automatically via operation Control key in Routing.

However, instead of auto goods movement, manual Goods Issue and receipt can be performed separately from confirmation.

Any failed goods movement due to a deficit of component stock can be reprocessed manually.

Activity costs such as machine, labor, etc. will also be updated in the production order during confirmation on an actual basis.

The order gets CNF (Confirmed) and DLV (Delivered) status after final confirmation and final Goods receipt.

If confirmation is posted wrongly, then we can cancel the confirmation and post it again with correct data.

Production Order Close

After the production order is delivered completely or we don’t want to execute the order further then Order should be technically completed.

After Order gets TECO status, it gets deleted from the stock/requirement list and is no longer considered in the material requirement planning run. All dependent reservations also get deleted from the system.

Next, we will look into each phase of SAP PP and learn how to operate the SAP PP module. the demand for the SAP PP module

Interested in this Sap Classes ? Fill Your Details Here

Error: Contact form not found.

WhatsApp us

WhatsApp us